Materials Testing Laboratory

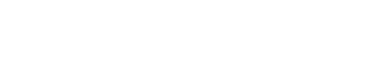

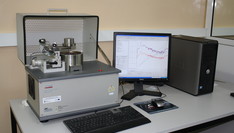

High Temperature Tribometer – THT (CSM Instruments)

Research capabilities:

- Assessment of the coefficient of friction, abrasive wear of rubbing surfaces using the Pin on Disk and Ball on Disk methods.

- The device allows to change the pressure force up to 60 [N], measure the friction force up to 20 [N], change the rotational speed in the range of I + 1500 [rpm], tests in a liquid medium up to a temperature of 250ºC or in air up to 800ºC.

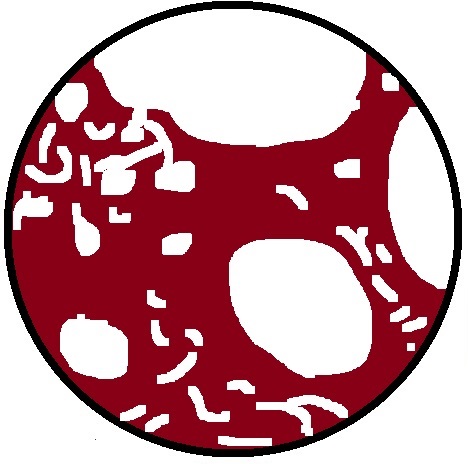

Neophot 2

Zeiss Neophot 2 - is an inverted metallographic microscope for research in the field of materials science. The microscope is equipped with a digital camera and a program for digital image analysis. The microscope also has;

- methods of observation in light: bright, dark and polarized,

- adapter with an output for a 35mm SLR camera and a built-in 4 "x5" large format camera,

- an attachment for macro photography,

- magnification range 10x - 2000x,

- 5x glasses,

- lenses: 1.25x; 2.5x; 6.3x; 12.5x; 25x; 50x; 100x,

- internal magnification changer: 0.8x; 1x; 1.25x; 1.6x; 2x.

The laboratory is also equipped with a Neophot 21 with similar equipment.

Portable hardness tester

Measurement of hardness by the Vickers method (HV) with automatic measurement, reading of the value and image of the imprint in the tested material enables quick and repeatable measurements on large objects or elements during operation.

- TIV hardness tester. The hardness tester enables direct measurements on the tested objects, registration of measurement results and archiving of images.

HANDY ERNST hardness tester

Research capabilities: The HANDY ERNST hardness tester uses the patented Esatest method to record the hardness-depth curve, enabling measurement in hard to reach places, with a small area, in any position of the measuring head. The measurement principle according to the Esatest method is a patented solution of Ernst, which is based on resistance changes in the electric circuit, which is a hardness tester with the tested detail.

- total load: 1- 10kG set by the operator;

- constant load increase with registration of depth and hardness;

- standard hardness scales: HV, HRC, HRB, HRA, HRF, Brinell HB30, Nmm2;

- minimum hole diameter: 20 mm;

- minimum measurement area on the plane: 2 x 2 mm.

Testing the intensity of abrasive wear

The abrasive wear intensity tests are carried out on a two-station ZS-2s device. The device carries out tests using the target-pin method. The test is carried out with the possibility of changing the loading force and the linear speed of friction. The material of the counter-sample is a disk and the sample is rubbed with a rectangular mandrel.

- The ZS-2s device. The device allows testing the intensity of abrasive wear under variable load up to and the linear speed of friction.

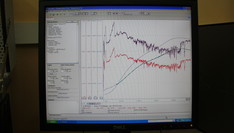

Fatigue strength tests

Fatigue strength tests are carried out on a specialized stand. The GZ1 device was designed especially for the fatigue tests of castings with a hardened surface layer. The device enables tests with the change of amplitude, frequency or loading force depending on the requirements.

- GZ1 device. Device with a control module and computer recording of results.

Laboratory freezer

- Arctico ultf 80 - Compact low temperature freezer in chest version, top loading, equipped with a single compressor cooling system with high capacity. Varnished steel housing. Temperature range: -40ºC to -86ºC, chamber capacity 71dm3.